Energy-Efficient Windows

New CommercialWhat are Energy-Efficient or High-Performance Windows?

Windows form part of the fenestration system of a building and play a key role in maintaining a highly insulated building envelope (see Insulation). The fenestration system, or arrangement of openings in a building envelope, determines a building’s HVAC requirements and daylighting.[1] Appropriately placed and selected energy-efficient or high-performance windows maximize natural light and minimize glare and heat gain or loss, decreasing dependence on electric lighting and HVAC systems and improving thermal comfort, energy-efficiency, and daylighting (see Daylighting and Glare and Heat Gain Reduction).[2]

Figure 1 – Windows and Skylights (Source: US DOE Energy Savers).

High-performance window technologies including low emissive or low-e glass panes, spacers, and insulated frames help prevent energy loss due to conduction, radiation, convection, and air leakage (see Air Infiltration). Low-e windows, treated with a microscopically thin coating, reduce heat flow. Spacers or tiny pieces placed between panes in double- or triple- paned windows, create an insulated space often filled with an inert gas such as argon or krypton to increase the window’s insulation properties (see Insulation). Advanced window technologies such as chromogenic windows and auto-operated windows and shading devices offer daylighting, solar heat gain control and ventilation benefits. Two types of chromogenic windows include thermochromic, which uses adhesive coating to adjust tinting passively with window surface temperature; and electrochromic, which use operable switches or automated building control systems to tint the window via electric current.[3] Operable windows and shading systems use auto-controlled devices that open and close at specific times of the day to manage ventilation levels or light levels and control indoor temperatures and manage solar heat gain.[4]

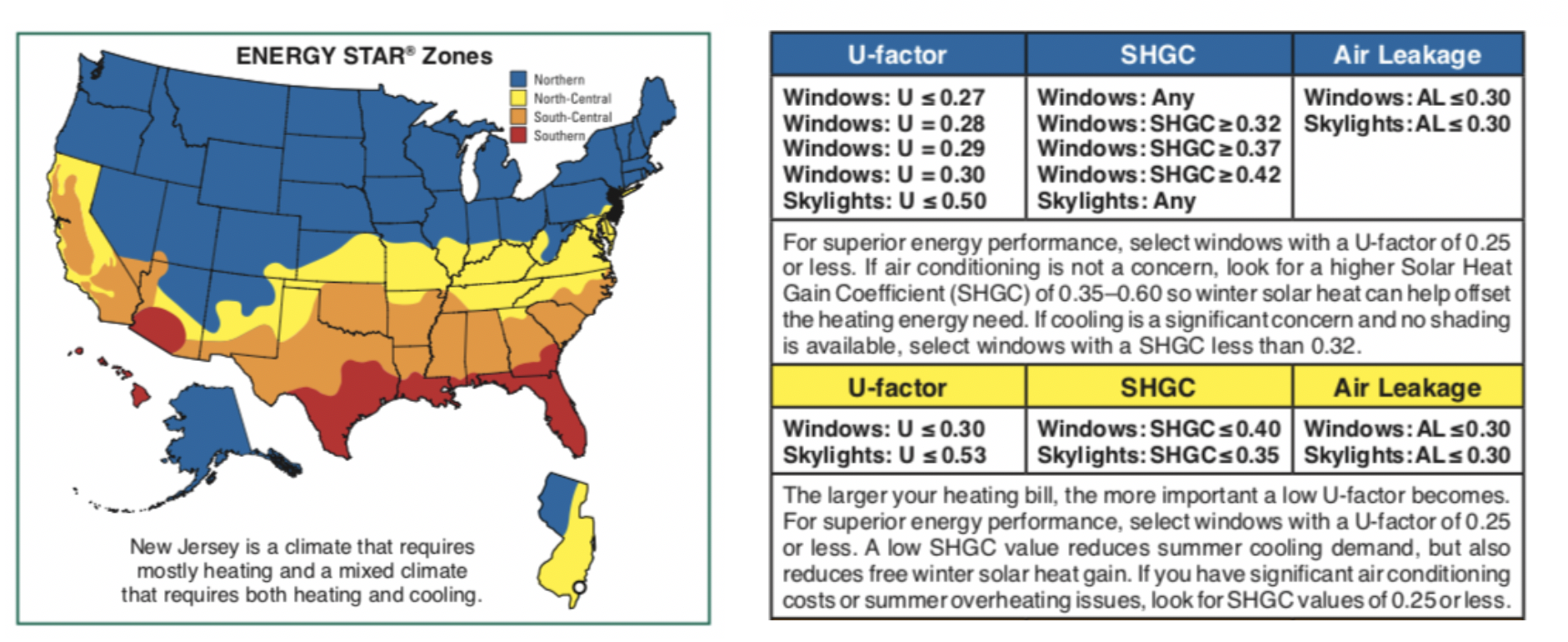

State and local energy codes, federal tax credits, and utility incentives, and ENERGY STAR base their criteria for energy-efficient windows on certified ratings by the National Fenestration Rating Council (NFRC). NFRC labels provide ratings for U-factor, Solar Heat Gain Coefficient (SHGC), Visible Light Transmittance (VT), and optionally Air Leakage (AL) and Condensation Resistance (CR) ratings (see Figure 2).

A window’s U-factor describes its rate of heat transfer or insulating properties. A lower U-factor indicates a window with higher resistance to heat flow, or a better-insulated window.[5] The Solar Heat Gain Coefficient (SHGC) indicates how much of the sun’s solar energy transmits through the window as heat. As the SHGC increases, the solar gain potential increases. Visible transmittance (VT) refers to the amount of visible light transmitted through the window. A higher VT means more daylight in a space. Advances in high-performance tinted glass and low-solar-gain low-e coatings reduce solar heat gain while maintaining visible transmittance. The Air Leakage (AL) rating describes leakage through cracks in the window assembly. Condensation Resistance (CR) rates windows on a range between 1 and 100 with higher numbers signaling increased resistance to condensation.

How to Incorporate Energy Efficient Windows

Use simulation programs such as the Efficient Windows Collaborative Window Selection Tool or Berkeley Lab’s RESFEN to determine energy-efficient and cost-effective window options. Look for the ENERGY STAR label, which sets standards for energy-efficiency that often exceed local energy code requirements.[6] When selecting a window based on performance, look for visible transmittance (VT) levels higher than (> 70%), especially for daylighting applications (see Daylighting).[7] For New Jersey’s Northern/Central climate zone, EnergyStar recommends SHGC of 0.4 (40%) or lower for buildings with moderate air conditioning requirements. Look for SHGC values of 0.25 or less for buildings with significant air conditioning costs or summer overheating problems.[8] For New Jersey’s Northern/Central climate zone, a U-factor of < 0.25 is recommended for high-performance buildings (see Fig. 2).[9]

Window performance depends on proper installation, sealing and flashing to prevent air leakage and water damage. Window manufacturers often provide detailed installation requirements and specifications for their products and may have recommendations of in-house installers and programs, 3rd party installers, or installer certification programs such as Installation Masters™. ASTM Standard E 2112 provides a nationally recognized standard for proper window installation.

Figure 2 – ENERGY STAR Recommended U-factor, SHGC and Air Leakage values for New Jersey’s Mixed Climate (Source: The Efficient Windows Collaborative).

Benefits

Energy-efficient windows contribute to the satisfaction, health, and productivity of building occupants by providing daylighting, reducing glare, providing views of nature, and regulating thermal comfort. By providing natural light, managing glare, and eliminating the need for window treatments that completely block out sunlight, high-performance windows can reduce electric lighting loads while at the same time reducing the ultraviolet (UV) and other solar radiation which causes fading of fabrics and furnishings. Energy-efficient windows designed as part of an overall energy management strategy can lead to mechanical equipment downsizing, saving capital costs, and reducing mechanical loads and operating expenses (see Properly-Sized HVAC System).

Costs

The cost of windows varies by project. Energy savings combined with improved thermal comfort, daylighting, and enhanced security benefits often justify the investment in high-performance windows. High-performance glazing can result in higher energy savings in connection with daylighting systems. Commercial buildings with adequately specified fenestration systems have the potential to reduce lighting and HVAC costs 10%–40%.[10] Maintenance and repair have a significant impact on the life-cycle cost of windows. Glass, a highly durable material only needs replacement when broken. Window frame durability depends upon maintenance. Framing materials typically have a useful life of 20 to 50 years depending upon the type of deterioration such as rot and corrosion. Sealants, caulks, tapes, and other glazing materials used to achieve weather-tightness typically have a useful life of 15 to 30 years depending upon thermal stress, movement, and environmental exposure.[11] Driven by the demand for large TV screens and recent improvements in thin glass technology, the cost of sub-millimeter glass compares to standard, double-strength glass.[12]

For up-to-date information on available incentives, visit the ENERGY STAR and the NJ Clean Energy Program websites.

Resiliency

In the event of a power outage, a building with energy-efficient windows maintains comfortable internal temperature for building occupants by reducing heat gain and reducing cooling loads during the summer months. During the winter months, energy-efficient windows provide better insulating properties compared to conventional windows while also offering daylighting, passive solar heating, and enhanced thermal comfort in the case of a power outage. Energy-efficient windows reduce reliance and stress on the grid and provide energy savings. In areas prone to flooding, wind-driven rain, snow storms or hurricanes, properly sealed and flashed windows protect against problems caused by water intrusion, including mold, warping, and structural damage.

[1] Whole Building Design Guide (WBDG) – Windows and Glazing http://www.wbdg.org/resources/windows.php (accessed April 10, 2018).

[2] Efficient Windows Collaborative. Understanding Windows. http://www.efficientwindows.org/understanding.php (accessed April 10, 2018).

[3] Jennifer King and Christopher Perry. 2017. “Smart Buildings: Using Smart Technology to Save Energy in Existing Buildings.” February 2017. American Council for an Energy-Efficient Economy. http://aceee.org/sites/default/files/publications/researchreports/a1701.pdf (accessed August 13, 2018).

[4] Christopher Perry. 2017. “Smart Buildings: A Deeper Dive into Market Segments.” December 2017. American Council for an Energy-Efficient Economy. http://aceee.org/sites/default/files/publications/researchreports/a1703.pdf (accessed August 13, 2018).

[5] The Efficient Windows Collaborative. U-Factor. http://www.efficientwindows.org/ufactor.php (accessed May 4, 2018).

[6] Energy Star. http://www.energystar.gov/index.cfm?fuseaction=find_a_product.showProductGroup&pgw_code=WI (accessed April 8, 2018).

[7] Whole Building Design Guide (WBDG). Windows and Glazing. https://www.wbdg.org/resources/windows-and-glazing (accessed April 8, 2018).

[8] Ibid.

[9] The Efficient Windows Collaborative. “Selecting Energy Efficient New Windows in New Jersey.” January 2016. http://www.efficientwindows.org/factsheets/New%20Jersey.pdf (accessed May 9, 2018).

[10] US DOE Office of Renewable Energy & Technology (Feb 2018) Windows and Envelope R&D Opportunities Workshop https://www.energy.gov/sites/prod/files/2018/03/f49/bto-windows-envelope-workshop-report-2018-03-01.pdf (accessed April 11, 2018).

[11] Philadelphia High-Performance Building Renovation Guidelines. http://www.phila.gov/pdfs/PhiladelphiaGreenGuidelines.pdf (accessed April 11, 2018).

[12] US DOE Office of Renewable Energy & Technology (Feb 2018) Windows and Envelope R&D Opportunities Workshop https://www.energy.gov/sites/prod/files/2018/03/f49/bto-windows-envelope-workshop-report-2018-03-01.pdf (accessed April 11, 2018).

Related Strategies

Resources

- Energy Star – Windows, Doors, and Skylights

- National Fenestration Rating Council (NFRC)

- Rensselaer Polytechnic Institute – Lighting Research Center

- US DOE – Building Technologies Office – Windows and Building Envelope

New Buildings Institute (NBI)

Whole Building Design Guide (WBDG)

Efficient Windows Collaborative