Chilled Beams

Existing CommercialWhat are Chilled Beams?

Chilled beams are room air recirculation systems integrated with acoustic ceilings or independently mounted that rely on radiant heat transfer from chilled or heated water coils to cool or heat a space. Chilled beams use water as a heat transfer medium instead of air to cool or heat a room, taking advantage of water’s higher heat transfer capacity and lower transport energy and freeing up space and saving energy through reduced fan energy and equipment requirements.[1] Chilled beams provide a flexible, easy to maintain, and energy-efficient alternative to variable air volume (VAV) systems and conventional air conditioning and heating systems, particularly for spaces that utilize individual zone control and experience moderate internal moisture loads.[2]

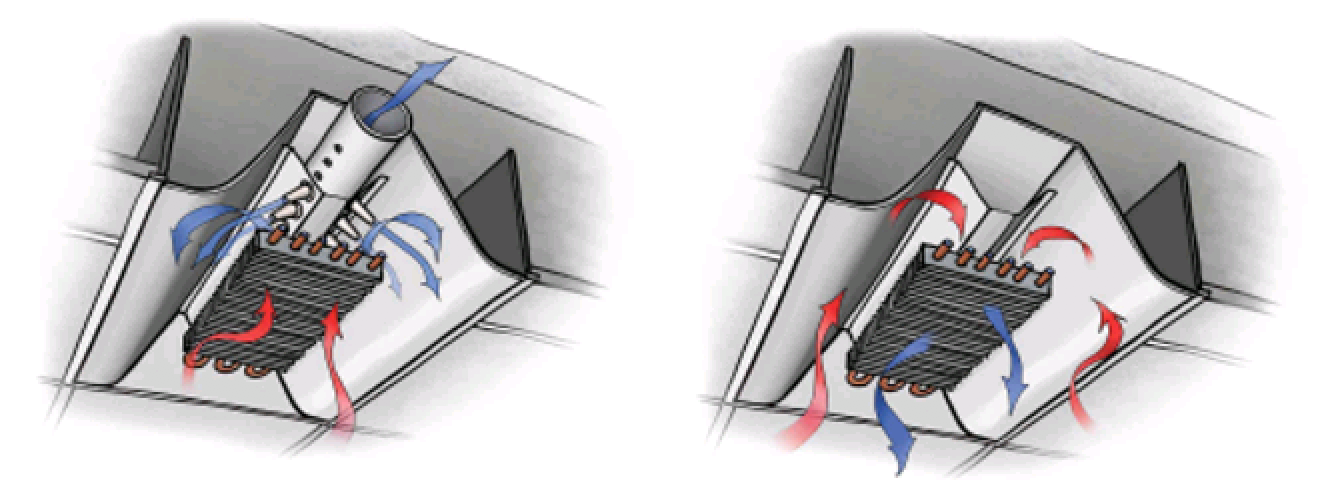

There are three types of chilled beam systems: passive, active, and multi-service. Passive chilled beams rely on the natural buoyancy of air to circulate through the heat exchanger, usually coils, to cool the air. In a passive system (most often used for cooling), hot air rises and becomes trapped in a space located above the chilled beams. Once the hot air interacts with the lower temperature beams, it naturally falls back into the room. Unlike active beams, passive beams are not directly connected to the ducted air supply and require a parallel ventilation system to handle dehumidification and latent loads and provide the primary air to drive the passive beam system.[3] Active systems direct air through the use of nozzles to the cooling or heating coils and allow for humidity control. Multi-purpose chilled beams can be used to supply other buildings services, such as lighting, speaker systems, IT systems, fire protection (sprinklers and detectors), acoustic insulation, Building Automation System sensors, and photocells.

Figure 1 – Active and Passive Chilled Beams (Source: US EPA).

How to Incorporate Chilled Beams

Chilled beams require specific applications but are often good candidates for retrofit projects and upgrades to HVAC systems in existing buildings due to their limited space requirements and ease of installation. However, chilled beams require specific applications and each chilled beam system design is unique, requiring project engineers to work closely with the manufacturer’s engineers in the design and selection of the chilled beam.[4]

According to best practice guidance from ASHRAE and REVHA chilled beams work best in applications with low air-side load fractions (or the percentage of the total air supply required by code for a zone) and in applications with high sensible heat ratios (or the percentage of the cooling load that is sensible compared to latent). For example, chilled beam systems can offer benefits over conventional systems if the sensible cooling load is substantially higher than the capacity of the air supplied to satisfy the latent loads.[5]

For comprehensive tools and guidance on designing, commissioning, and operating active and passive beam systems refer to the joint publication by ASHRAE and REVHA, “Active and Passive Beam Application Design Guide.” Available for purchase at https://www.ashrae.org

ANSI/ASHRAE Standard 200-2018, Methods of Testing Chilled Beams, establishes testing methods and procedures for determining the performance of chilled beams. Certification programs (Eurovent, AHRI) guarantee the accuracy of manufacturers’ technical data.

Example

New Jersey Institute for Food, Nutrition, and Health, Rutgers University, New Brunswick, NJ.

The IFNH building at Rutgers University, designed by Ballinger Architects finished in 2015 and built to LEED Gold standards is the first Rutgers University building to incorporate chilled beams as part of the building’s open laboratory design.

Fig 2. New Jersey Institute for Food, Nutrition, and Health. (Source: Rutger University).

Benefits

Chilled beams have the potential to save significant amounts of energy and operating costs compared to completely air-based systems because they move heat more efficiently by using water instead of air as the heat transfer fluid, reducing the reheat and fan energy required to operate the system.[6] Chilled beams also increase the usable floor space and ceiling height in a building by eliminating additional ductwork and equipment space requirements and allowing for modular configurations and flexible installations. Other advantages include enhanced thermal comfort (e.g., uniform air distribution), acoustic control (e.g., quiet operation) and indoor air quality (e.g., utilize 100% outside air and limit room to room air recirculation).[7] Finally, chilled beams offer lower maintenance and repair costs due to fewer mechanical components than conventional HVAC systems.

Cost

The cost of chilled beams varies depending on the design and application. Chilled beams often have higher materials costs than conventional VAV systems but lower installation, maintenance, and energy costs. For example, by requiring fewer air exchanges, chilled beams can result in the downsizing of ductwork, air-handling units, exhaust fans, chillers, and boilers, reducing first costa and helping to offset the cost of chilled beam infrastructure.[8] The growing number of certified manufacturers and installers and available incentives are also helping to make chilled beams more cost competitive with conventional technologies.

See the NJ Clean Energy Program for current incentives and programs http://www.njcleanenergy.com

Resiliency

Chilled beams contribute to resiliency by decreasing energy consumption, including peak loads, which decreases reliance and stress on the electricity grid.

[1] ASHRAE and REHVA. 2015. “Active and Passive Beam Application Design Guide.”

[2] ASHRAE and REHVA. 2015. “Active and Passive Beam Application Design Guide.”

[3] Energy Design Resources. 2010. E-News #69: Chilled Beams. February 2010.

https://energydesignresources.com/resources/e-news/e-news-69-chilled-beams.aspx (accessed Jan 8, 2019).

[4] The American Society for Healthcare Engineering (ASHE), the Association for the Healthcare Environment (AHE), and the Association for Healthcare Resource & Materials Management (AHRMM) of the American Hospital Association (AHA). 2012. Sustainability Roadmap for Hospitals – “Reduce energy-consumption and improve comfort with an active chilled beam system.” http://www.sustainabilityroadmap.org/pims/265#.XDOOYi2ZNAZ Accessed Jan 8, 2019).

[5] ASHRAE and REHVA. 2015. “Active and Passive Beam Application Design Guide.”

[6] ASHE et al. 2012. Sustainability Roadmap for Hospitals – “Reduce energy-consumption and improve comfort with an active chilled beam system.” http://www.sustainabilityroadmap.org/pims/265#.XDOOYi2ZNAZ Accessed Jan 8, 2019).

[7] ASHRAE and REHVA. 2015. “Active and Passive Beam Application Design Guide.”

[8] ASHE et al. 2012. Sustainability Roadmap for Hospitals – “Reduce energy-consumption and improve comfort with an active chilled beam system.” http://www.sustainabilityroadmap.org/pims/265#.XDOOYi2ZNAZ Accessed Jan 8, 2019).