Construction Indoor Air Quality (IAQ) Management Plan

New ResidentialWhat is a Construction Indoor Air Quality (IAQ) Management Plan?

A construction indoor air quality management plan is a step-by-step approach to protecting indoor air during construction and pre-occupancy. Several studies show that pollutant levels indoors are two to five times greater than outdoors. Poor indoor air quality can cause dizziness, asthma, fever, lung cancer and many other health problems.[1],[2]Implementing protective practices during the construction phase can help prevent poor indoor air quality.

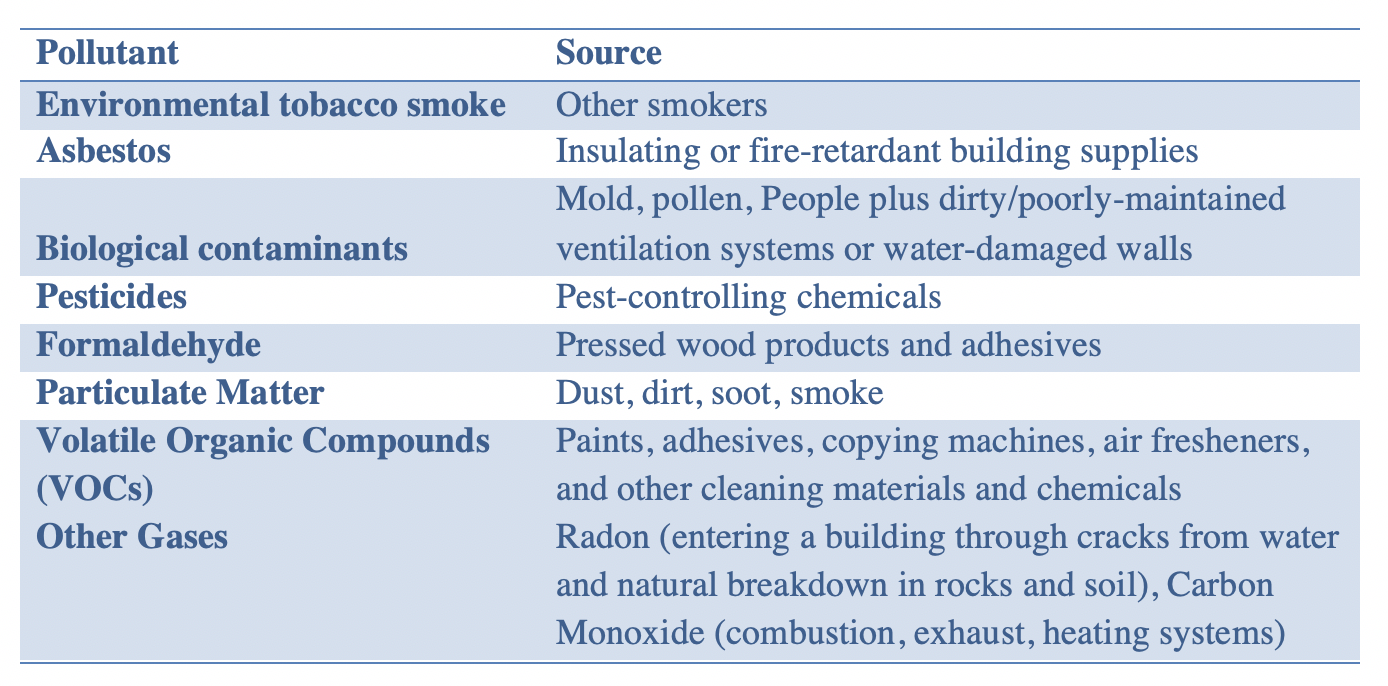

Strategies, such as protecting absorptive materials from exposure to moisture to prevent mold growth and using air filters when running equipment during the installation of interior duct systems or during power equipment use (sanding) reduces the risk of poor air quality. These strategies help to protect the workforce during construction, and building occupants after the structure is built (see Table 1 for a list of conventional sources of air pollution).

Table 1: Common Sources of Indoor Air Pollution[3]

How to Implement a Construction IAQ Management Plan

The Construction IAQ Management Plan is developed during the design phase and implemented at the outset of the construction phase (see Integrated Design Process). The IAQ plan also addresses the period between the completion of construction and occupancy. Control emissions during both construction and post-construction by selecting low-emitting materials whenever possible, holding off on installation of absorbent materials (e.g., carpet, ceiling tiles) until emissions from construction contaminants (e.g., oils, adhesives, paints) have subsided, increasing ventilation during periods of high emission, protecting ducts from dust and contaminants and delaying occupancy until emissions have dissipated. If occupants are present in the building, isolate construction contaminants by establishing a full enclosure around the construction zone, establishing negative pressure within containment zone with exhaust fans and making sure that contaminants don’t re-enter the building through open windows or HVAC system intakes.[4] Also, the building should be flushed out before occupancy. Flush out involves forcing large quantities of outdoor air through the new building to remove pollutants before occupancy.

Benefits

- Protects the health of the construction team (and building occupants if the building remains occupied) during the construction phase.

- Protects the health of the occupants following construction.

- Prevents potential health problems by reducing airborne contaminants.

Costs

When combined with an integrated design process, developing and implementing an IAQ management plan is not a significant financial burden but requires extensive coordination with the project team.

Resiliency

Implementing a comprehensive construction IAQ management plan helps ensure the building and building systems begin operation without contaminants or elements that can degrade indoor air quality. Sound IAQ management contributes to operation efficiencies through protecting building systems and indoor environmental quality for occupants. Good indoor air quality and efficient operations help contribute to a building, building systems and building occupants’ ability to withstand, recover from and adapt to extreme or unpredictable events.[5]

[1] See US EPA’s webpage on Health Effects due to poor indoor air quality for a list of identified illnesses. (accessed April 20, 2018).

[2] Also see Health Impact at WHO’s webpage on Indoor Air Pollution and Health (accessed April 20, 2018).

[3] US EPA. Indoor Pollutants and Sources. https://www.epa.gov/indoor-air-quality-iaq/indoor-pollutants-and-sources (accessed December 18, 2018).

[4] US EPA. Indoor Air Quality (IAQ). https://www.epa.gov/indoor-air-quality-iaq/renovation-and-new-construction-text-module-indoor-air-quality-building#cr52 (accessed December 19, 2018).

[5] US EPA. Indoor Air and Climate Readiness. https://www.epa.gov/sites/production/files/2014-08/documents/climate_readiness.pdf (accessed December 18, 2018).