ENERGY STAR Equipment and Plug Loads

Existing CommercialWhat is ENERGY STAR Equipment and Plug Loads?

ENERGY STAR, a joint program of the United States Environmental Protection Agency (US EPA) and the United States Department of Energy (US DOE), labels energy-efficient products and practices using third-party certified testing to guarantee quality and performance.[1]

ENERGY STAR, a joint program of the United States Environmental Protection Agency (US EPA) and the United States Department of Energy (US DOE), labels energy-efficient products and practices using third-party certified testing to guarantee quality and performance.[1]

On average, computers and electronics account for 7% of energy use in commercial buildings, and other uses or miscellaneous electronic loads (MELs) or plug load accounting for 38%.[2] Plug load refers to any device plugged into the building’s electrical system including computers and monitors, task lighting, televisions, vending machines, kitchen equipment, and cell phone chargers.[3] Replacing conventional appliances and office equipment and other electronic devices at the end of their useful life with ENERGY STAR labeled products and managing plug loads can save money through reduced energy consumption and associated cost savings. ENERGY STAR products are 10-25% more efficient than required by the federal standard.[4] Labeled products include commercial electronics such as computers as well as several types of appliances, lighting fixtures, HVAC equipment, and water heaters.

Most appliance and electronic stores carry ENERGY STAR certified equipment. For a complete list, see ENERGY STAR certified products.

How to Incorporate ENERGY STAR Equipment and Plug Loads

Require ENERGY STAR appliances and equipment as part of your procurement and purchasing policy and educate staff on the benefits of labeled equipment and energy-saving behaviors.

- Step 1 – Create an inventory list of necessary equipment.

- Step 2 – Purchase the most energy-efficient devices for the job. Estimate potential energy and cost savings using ENERGY STAR calculators.

- Step 3 – Check for available incentives and rebates:

Energy Star Rebate Finder

Database of State Incentives for Renewables and Efficiency (DSIRE)

NJ Clean Energy Program Commercial Building Incentives - Step 4 – Follow the manufacturer’s instructions or hire a professional installer as poor installation can affect the performance of equipment.

- Step 5 – Manage plug loads. Eliminate or unplug unnecessary devices. Turn off or power down devices when not in use and use power management settings, timers, and advanced power plugs. Engage staff and make sure they understand why, when, and how to power down.

Examples

ENERGY STAR Purchasing and Procurement Case Studies

GSA Green Proving Ground (GPG): Advanced Power Strips for Plug Load Control

A study conducted by the GSA Green Proving Ground Program found that advanced power strips (APS) that use pre-programmed timers to turn off equipment can reduce energy consumption by an average of 26% at workstations and by 50% in printer rooms and kitchens.

Benefits

By avoiding the need to generate electricity in the first place, energy-efficiency reduces emissions and air pollution related to producing energy including greenhouse gases, acidifying substances, ozone precursors, and particulate matter or precursors.[5] The installation of ENERGY STAR qualified equipment and properly managing plug loads can reduce energy usage and lower energy and utility bills.[6]

- Extends product life and decreases maintenance

- Increase leasing and resale value of an energy-efficient building

- Lower operating costs

Costs

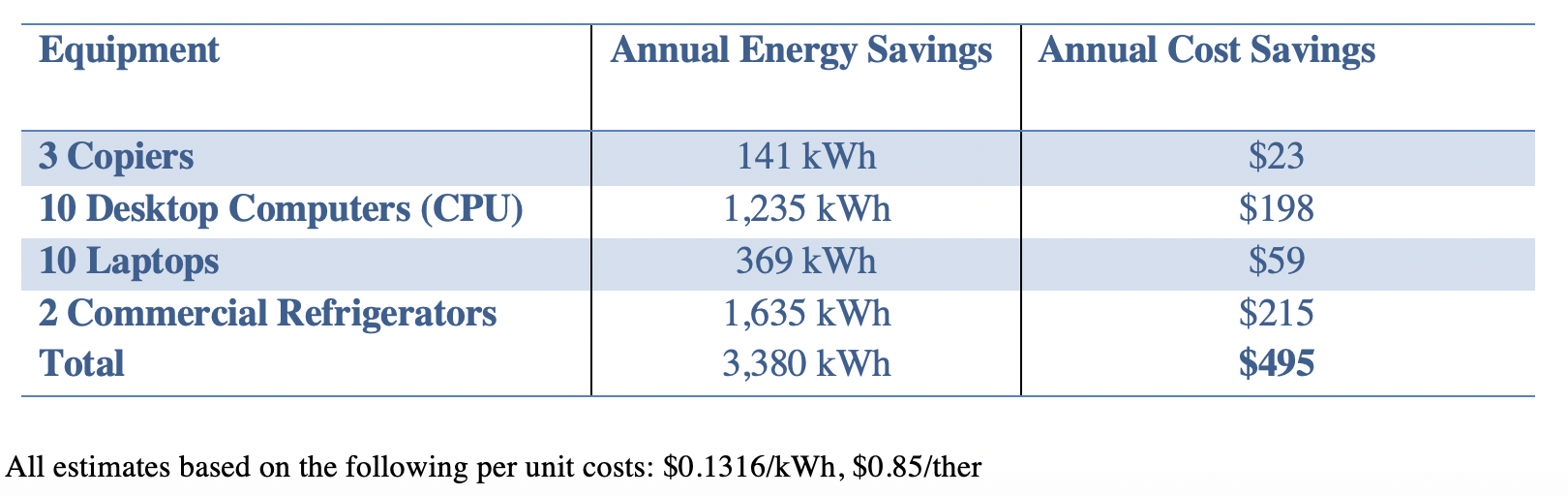

ENERGY STAR cost savings calculators provided the following data which shows expected energy savings by switching from a conventional product to an ENERGY STAR product. The example includes common appliances and office equipment found in existing municipal buildings. Assumptions based on ENERGY STAR value assumptions for the various products listed.

Table 1 – Scenario based on a 20,000 sq. ft. building[7]

Table 1 – Scenario based on a 20,000 sq. ft. building

Resiliency

Use of ENERGY STAR certified products and managing plug loads reduces energy usage, increasing grid reliability and reducing utility costs.

[1] ENERGY STAR. http://www.energystar.gov/index.cfm?c=about.ab_index (accessed April 17, 2018).

[2] Lisa Schwartz et al. “Electricity end uses, energy-efficiency, and distributed energy resources baseline.” Energy Analysis and Environmental Impacts Division Lawrence Berkeley National Laboratory. January 2017. Page 24. https://www.energy.gov/sites/prod/files/2017/01/f34/Electricity%20End%20Uses,%20Energy%20Efficiency,%20and%20Distributed%20Energy%20Resources.pdf (accessed April 18, 2018).

[3] New Buildings Institute. 2012. “Plug Load Best Practices Guide: Managing Your Office Equipment Plug Load.” https://newbuildings.org/wp-content/uploads/2015/11/PlugLoadBestPracticesGuide1.pdf (accessed April 16, 2018).

[4] ENERGY STAR. “Lighting, Appliances, Office Equipment.” http://www.energystar.gov/index.cfm?c=pt_reps_res_retail.pt_reps_res_retail (accessed April 16, 2018).

[5] Lisa Schwartz et al. “Electricity end uses, energy-efficiency, and distributed energy resources baseline.” Energy Analysis and Environmental Impacts Division Lawrence Berkeley National Laboratory. January 2017. https://www.energy.gov/sites/prod/files/2017/01/f34/Electricity%20End%20Uses,%20Energy%20Efficiency,%20and%20Distributed%20Energy%20Resources.pdf (accessed April 18, 2018).

[6] ENERGY STAR. ENERGY STAR Qualified Appliances. https://www.energystar.gov/buildings/building_recognition/building_certification/reasons_get_certified (accessed April 17, 2018).

[7] Table 1 – Expected energy savings by switching from a conventional product to an ENERGY STAR product. Annual Electric Savings (MWh) calculated per unit. All estimates based on the following per unit costs also used in New Jersey state energy plans and studies:14 $0.1316/kWh, $0.85/therm. Average Paybacks calculated with the following equation for each appliance:

[average incremental cost] – [annual cost savings]*[years] = 0 Or: [average payback in years] = [average incremental cost] / [annual cost savings]