Insulation

New CommercialWhat is Insulation?

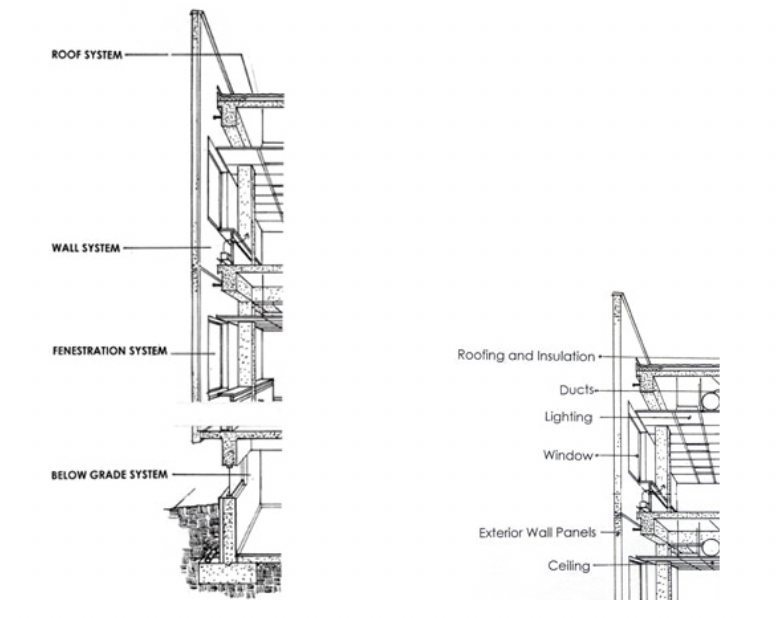

Insulation includes materials that reduce the amount of heat lost from a building. Properly insulating a new building relates to creating an efficient building envelope. The building envelope or the physical structure between the inside of the building and the outside environment includes walls, windows, doors, roof systems, and the foundation.[1] A properly insulated building envelope increases the efficiency of the heating, ventilation, and air-conditioning (HVAC) system, reducing energy costs while increasing occupant thermal comfort by acting as a thermal barrier and controlling indoor temperature and humidity levels.[2] It is important to note that insulation only helps reduce air and heat flow in the space where it is contained. Therefore it is most effective when the building is also correctly sealed against excess air infiltration (see Air Infiltration strategy).[3]

Figure 1. Envelope Systems of a typical building (Source: Whole Building Design Guide).

How to Incorporate Insulation

A highly insulated building envelope requires an integrated design approach during the pre-design phase of a project that views the building as a whole system and coordinates all of the building elements that need to be adequately insulated (see Integrated Design Process). Factors to consider include building orientation and daylighting (windows), material selection (walls, doors, roof, foundation), HVAC and electrical system (mechanical equipment), and the local climate (see Building Orientation and Daylighting strategies). The outdoor environment can impact the effectiveness of a building’s envelope. The North American Insulation Manufacturers Association (NAIMA) provides insulation guidelines for specific climate zones and building types. In the indoor environment, thermal loads may come from mechanical equipment and lighting. Windows and exterior doors, which are part of the fenestration system of a building, can influence the HVAC requirements and also the amount of daylight. For example, HVAC systems are a significant component of the overall energy demand for new commercial buildings. However, a more efficiently insulated building envelope can reduce the energy requirements of the building’s HVAC system by minimizing the loss of conditioned air to the outside (see Properly Sized HVAC Equipment strategy). The building’s layout and interior design elements can impact thermal heat exchange. Specific building materials conduct heat at differing rates (see Thermal Massing strategy), and building components such as walls, joints, studs, and others can act as a conduit for heat conduction. Finally, a highly insulated roof combined with solar reflective roofing materials offer the opportunity to save on heating and cooling costs, improve thermal comfort, and reduce peak cooling loads (see Cool Roof sstrategy).[4] An analysis of these factors early in the design process helps to determine the optimal building footprint to building orientation and the selection of building materials to maximize the energy efficiency benefits of a highly insulated building envelope.

Insulation ratings refer to R-value or resistance to heat flow. [5] An insulation’s material composition and thickness contribute to its R-value. A higher R-value indicates higher expected thermal performance. However, more is not always better, as there is a point of diminishing returns with insulation (i.e., the intersection between cost and energy savings).[6] Look for Energy Star certified insulation tested for performance and safety standards. Refer to resources such as the North American Insulation Manufacturers Association (NAIMA) for recommended R-values for the local climate and more specific information about insulation materials.

The following list includes examples of both widely-used and more innovative insulation materials and wall systems for commercial buildings:[7]

- Continuous and Cavity Insulation. Continuous insulation runs uninterrupted over structural membranes, avoids thermal bridging and is installed on the exterior surface of the building envelope.[8] Cavity insulation is installed between structural components such as wood studs.

- Composite Metal Panels consist of two sheets of metal adhered to a core material and include:[9]

- Foamed-Insulation Core Metal Wall Panels

- Laminated-Insulation Core Metal Wall Panels

- Honeycomb Core Metal Wall Panels

- Exterior Insulation Finish Systems (EIFs) consists of exterior wall cladding made of rigid insulation boards. The polymer-based (PB) system is most popular and consists of closed expanded polystyrene (EPS) insulation finished with a polymeric (organic) bonded aggregate and cement reinforced with a glass mesh.[10] Being lightweight and low cost, and the ability to achieve different aesthetic effects make EIFs a popular choice.[11]

- Insulated Concrete Forms (ICFs) consists of concrete walls poured inside foam insulation forms with steel reinforcing and stacked as interlocking blocks.[12] Insulated concrete block or concrete masonry units (CMUs) form prefabricated blocks applied like traditional block wall construction.

- Structural Insulated Panels (SIPs) consist of an insulating foam core placed between two structural panels, typically oriented strand board (OSB) or fiber cement panels.[13]

- Vacuum Insulated Panels (VIPs) consist of a solid interior layer of a high R-value material wrapped in an exterior layer of airtight foil with a vacuum drawn inside the airtight foil.[14] They can achieve an R-value of 50 without adding bulk, making them cost-effective on roofs.[15]

Examples

US Post Office and Courthouse, Camden, NJ

This roofing project, sponsored by the General Service Administration (GSA) Green Proving Ground (GPG) program, installed Vacuum Insulated Panels (VIPs) at the U.S. Post Office and Courthouse in Camden, New Jersey. VIPs consist of a solid interior layer of a high R-value material wrapped in an exterior layer of airtight foil with a vacuum drawn inside the airtight foil.[16] The study used energy modeling and thermographic images and found that VIPs can offer a favorable payback in one-story buildings in regions with extreme climates and high utility costs.[17] They can achieve an R-value of 50 without adding bulk, making them cost-effective on roofs.[18]

Benefits

A properly designed and installed insulation system offers the following benefits.[19]

- Reduces energy costs

- Prevents moisture condensation

- Reduces capacity and size of new mechanical equipment

- Enhances acoustical performance through reduced noise levels

- Increases indoor environmental quality and thermal comfort.[20]

- Provides fire protection

Costs

The cost of implementing a highly insulated building envelope vary depending on the size and orientation of the home, climate, design elements, and the type of insulation and building material. Annual energy savings and incentives offered by the NJ Office of Clean Energy can help offset upfront costs.

Resiliency

A properly insulated building offers several essential resiliency benefits. In the event of a power outage, highly insulated buildings protect against heat loss in the winter and heat gain in the summer, helping to maintain comfortable internal temperatures for building occupants, and reducing stress on the grid. Wall assembly systems (with insulating properties) such as precast concrete panels, insulated concrete forms (ICFs), and structural insulated panels (SIPs) offer resistance to hazards such as fire, wind, earthquakes, and floods, and improve indoor environmental quality through resistance to mold.[21]

[1] Arnold, Chris. 2016. “Building Envelop Design Guide.” Whole Building Design Guide (WBDG). National Institute of Building Sciences (NIBS). https://www.wbdg.org/guides-specifications/building-envelope-design-guide/building-envelope-design-guide-introduction (accessed May 29, 2018).

[2] US DOE | Better Buildings. “Building Envelope.” https://betterbuildingsinitiative.energy.gov/alliance/technology-solution/building-envelope (accessed May 29, 2018).

[3] US DOE: Insulation Fact Sheet. 2008. https://web.ornl.gov/sci/buildings/docs/factSheets/Insulation-FactSheet-2008.pdf (accessed May 4, 2018).

[4] Vivian Loftness et al. 2012. “State of the Art in Enclosure Technologies and Integrated Systems for 50% Energy Savings in Existing Commercial Buildings.” Consortium for Building Energy Innovation. Page 23. http://cbei.psu.edu/wp-content/uploads/2016/07/State-of-the-Art-in-Enclosure-Technologies.pdf (accessed June 4, 2018).

[5] US DOE: Energy Saver. “Insulation” https://www.energy.gov/energysaver/weatherize/insulation (accessed May 29, 2018).

[6] Rutgers Center for Green Building (RCGB). 2011. “Costs and Benefits of Residential Energy Efficiency Investments.” Prepared for the New Jersey Association of REALTORS® Governmental Research Foundation. Page 21 http://rcgb.rutgers.edu/costs-and-benefits-of-residential-energy-efficiency-investments/ (accessed May 9, 2018).

[7] US DOE: Better Building Solution Center. Building Envelope Webinars for Walls

https://betterbuildingssolutioncenter.energy.gov/toolkits/building-envelope-webinars-walls (accessed May 29, 2018).

[8] US DOE Building Energy Codes Resource Center. “Cavity and Continuous Insulation.”

https://www.energycodes.gov/sites/default/files/documents/ta_cavity_and_continuous_insulation_in_rescheck.pdf (accessed May 29, 2018).

[9] Zwayer, Gary L. 2016 “Exterior Insulation and Finish Systems (EIFs).” Whole Building Design Guide. National Institute of Building Sciences. https://www.wbdg.org/guides-specifications/building-envelope-design-guide/wall-systems/exterior-insulation-and-finish-system-eifs (accessed May 29, 2018).

[10] Lstiburek, Joseph. 2007. “EIFs: Problems and Solutions.” Building Science Corporation. https://buildingscience.com/documents/digests/bsd-146-eifs-problems-and-solutions (accessed May 29, 2018).

[11] Zwayer, Gary L. 2016. “Exterior Insulation and Finish Systems (EIFs).” Whole Building Design Guide. National Institute of Building Sciences. https://www.wbdg.org/guides-specifications/building-envelope-design-guide/wall-systems/exterior-insulation-and-finish-system-eifs (accessed May 29, 2018).

[12] US DOE: Building America Solution Center: ICFs. https://basc.pnnl.gov/resource-guides/insulated-concrete-forms-icfs#quicktabs-guides=1 (accessed May 29, 2018).

[13] Structural Insulated Panel Association (SIPA). “What are SIPS?” https://www.sips.org/about/what-are-sips (accessed May 29, 2018).

[14] Dan Howell et al. “Vacuum Insulated Panels (VIPs) in a roofing application of US Post Office and Courthouse Camden, NJ.” March 2014. ORNL https://www.gsa.gov/cdnstatic/GPG_Vacuum_Insulated_Panels_03-2014.pdf (accessed May 29, 2018).

[15] GSA. Green Proving Ground Program. “Vacuum Insulated Panels in Roofing Applications.” March 2016. https://www.gsa.gov/governmentwide-initiatives/sustainability/emerging-technologies/published-findings/building-envelope/vacuum-insulated-panels (accessed May 29, 2018).

[16] Dan Howell et al. “Vacuum Insulated Panels (VIPs) in a roofing application of US Post Office and Courthouse Camden, NJ.” March 2014. ORNL https://www.gsa.gov/cdnstatic/GPG_Vacuum_Insulated_Panels_03-2014.pdf (accessed May 29, 2018).

[17] Ibid.

[18] GSA. Green Proving Ground Program. “Vacuum Insulated Panels in Roofing Applications.” March 2016. https://www.gsa.gov/governmentwide-initiatives/sustainability/emerging-technologies/published-findings/building-envelope/vacuum-insulated-panels (accessed May 29, 2018).

[19] National Insulation Association (NIA). 2018 “Benefits of Insulation.” https://insulation.org/about-insulation/benefits-of-insulation/ (accessed May 29, 2018).

[20] Arnold, Chris. 2016. “HVAC Integration of the Building Envelope.” Whole Building Design Guide. National Institute of Building Sciences. http://wbdg.org/guides-specifications/building-envelope-design-guide/building-envelope-design-guide-introduction (accessed May 29, 2018).

[21] New Jersey Climate Adaptation Alliance (NJCAA). 2014. The Role of Buildings in Climate Adaptation. Climate Change Preparedness in New Jersey. Page 11. Edited by Jennifer Senick. https://njadapt.rutgers.edu/docman-lister/resource-pdfs/111-green-bulding/file (accessed May 7, 2018).

Resources

- Air Barrier Association of America

- Continuous Insulation

- Insulation Institute

- Metal Building Manufacturers Association

- North American Insulation Manufacturers Association (NAIMA)

- NJ Clean Energy Program

- Structural Insulated Panel Association

- Whole Building Design Guide – Envelope

- US DOE: Better Buildings – Building Envelope